|

Load |

Speed |

|

1500N |

4mm/s or 5.7mm/s |

|

1000N |

6mm/s or 8.8mm/s |

|

750N |

10mm/s |

|

600N |

12mm/s |

|

500N |

15mm/s |

|

400N |

20mm/s |

|

300N |

25mm/s |

|

200N |

30mm/s |

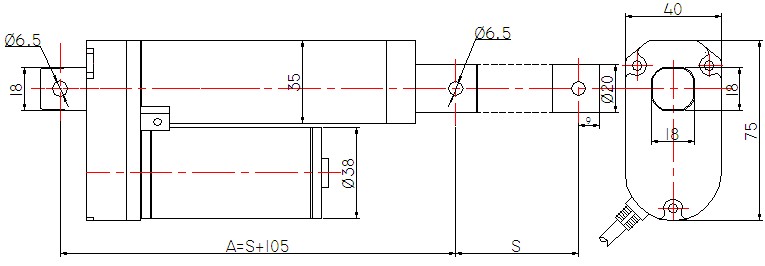

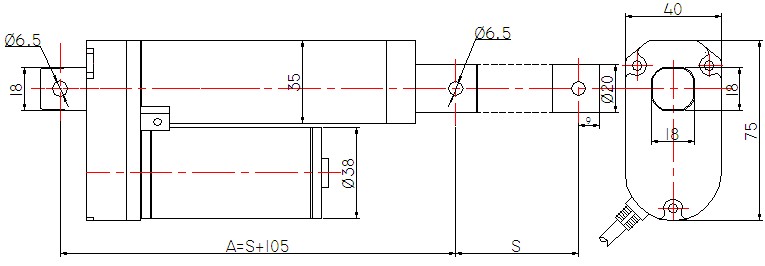

ARF03 Mini Linear Actuators

Specifications

Input voltage: 12V/24 VDC

Max.Load: 1500N

Standard Stroke: 30/50100/150/200/250/300mm,

can produce as your request.

Speed: 4-25mm/s

Duty Cycle: 10%, work 2 minutes need to rest 18 minutes

Ambient Temperature: 一25℃ to 65℃

IP Grade: IP65

Built-in integral limit switch, not adjustable after leaving factory

Low noise design, dB≤50

Min.install size: stroke+105mm

Certificates:CE&RoHS

The ARF03 Mini Tube Electric Linear Actuator has several advantages that make it excellent in a variety of applications. First, its compact design and small size make it suitable for scenarios with limited space, optimizing equipment layout and installation. Secondly, the use of high-efficiency DC motors and precision transmission systems ensures efficient energy conversion and significantly reduces energy consumption. Its precise positioning function achieves high-precision and highly repeatable linear motion through advanced control technology.

These advantages make ARF03 widely used in many fields. In industrial automation, it is used for the handling and assembly of precision parts; in medical equipment, it is used for surgical instruments and patient position adjustment; in consumer electronics, it is used for camera adjustment and smart home equipment. In addition, ARF03 is also widely used in laboratory automation and small robot systems, providing efficient and reliable solutions for various precision control tasks.

|

Load |

Speed |

|

1500N |

4mm/s or 5.7mm/s |

|

1000N |

6mm/s or 8.8mm/s |

|

750N |

10mm/s |

|

600N |

12mm/s |

|

500N |

15mm/s |

|

400N |

20mm/s |

|

300N |

25mm/s |

|

200N |

30mm/s |

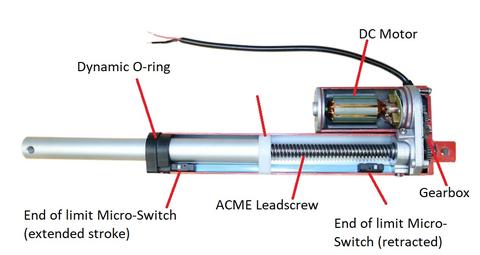

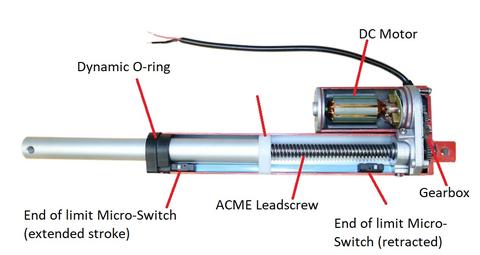

ARF03 Mini Tube Electric Linear Actuator is a compact electric linear actuator. Its operating principle is based on the motor-driven screw transmission system to achieve linear motion control.

Brief Introduction to Operating Principle:

The operating principle of ARF03 Mini Tube Electric Linear Actuator mainly includes three core components: motor, screw transmission system and controller. The motor converts rotational motion into linear motion through the transmission system to achieve linear propulsion. The controller is responsible for managing the operation of the motor to achieve accurate control of linear motion.

Motor: ARF03 Mini Tube Electric Linear Actuator is equipped with a DC motor or stepper motor. The motor generates rotational motion by transmitting current, converts mechanical energy into power, and provides driving force for the screw transmission system.

Screw transmission system: The screw transmission system of ARF03 Mini Tube Electric Linear Actuator consists of a screw and a nut. The motor drives the screw by rotation, and the screw converts rotational motion into linear motion, so that the nut moves on the screw and promotes the linear motion of the actuator.

Controller: The ARF03 Mini Tube Electric Linear Actuator is equipped with a controller to manage the operation of the motor and the speed, position and other parameters of the linear motion. The controller can be programmed according to user needs to achieve accurate linear motion control.

Operation process:

After receiving the command, the controller sends a signal to the motor to start the motor.

The motor starts to rotate and drives the screw to rotate.

The screw drive system converts the rotational motion into linear motion, causing the nut to move on the screw.

The movement of the nut drives the actuator to achieve linear motion and complete the work task.

The controller monitors the speed and position of the linear motion and adjusts the speed of the motor according to the set parameters to achieve accurate linear motion control.

ARF03 Mini Tube Electric Linear Actuator is a small electric linear actuator with many design features that make it widely used in various fields.

Compact design: The ARF03 Mini Tube Electric Linear Actuator adopts a compact tubular housing design, which enables it to perform well in application scenarios with limited space. Whether in industrial automation production lines or in medical equipment, compact design can effectively save space, making the equipment more flexible and easy to install.

High precision: ARF03 Mini Tube Electric Linear Actuator uses a high-precision screw drive system inside to achieve very precise linear motion control. In applications that require precise positioning and high-precision operation, ARF03 Mini Tube Electric Linear Actuator provides reliable performance to ensure stable operation of the equipment.

High efficiency: The motor of ARF03 Mini Tube Electric Linear Actuator adopts a high-efficiency design, provides efficient energy conversion, reduces energy consumption, and extends service life. In industrial production, high-efficiency electric linear actuators can improve production efficiency, save energy costs, reduce operating costs, and improve overall competitiveness.

Lightweight: ARF03 Mini Tube Electric Linear Actuator adopts lightweight materials and structural design, which is light and easy to install and carry. In applications that require frequent movement or adjustment of position, lightweight design can reduce labor intensity, improve work efficiency, reduce the overall weight of the equipment, reduce load, and extend the life of the equipment.